AUTOBRIDGE FOR AUTOMOTIVE INDUSTRIES

LET'S SET THE IDEAL CONDITIONS FOR YOUR NEXT LAUNCH

AUTOBRIDGE FOR AUTOMOTIVE INDUSTRIES

LET'S SET THE IDEAL CONDITIONS FOR YOUR NEXT LAUNCH

Better Vehicle Launches Start Here

about us

AUTOBRIDGE is a U.S-based (global) manufacturing & engineering services firm specializing in providing process

development, prototype and pre-production parts for automotive manufacturers and tier one suppliers. Together with 3CON, one of the global forerunners in the manufacturing of interior production systems,

we can help you bridge the gap between design, prototype and series production.

And Beyond The Launch ...

Our skills and experience can be equally beneficial beyond the launch phase. Leverage our expertise and capacity to drive on-going

cost-reductions, optimize capacity and manage low-volume service and production critical for your profitability.

Our Mission

We want to help you improve your profitability. Whether it is helping you through a launch, planning your next project, or providing you manufacturing capacity to produce your product when needed. We will flex to your needs. Our mission is your success.

Our Team

Our seasoned team has led many vehicle launches for various OEMs around the globe and are ready to put their expertise to work for you.

Our Core Strengths

We leverage our core strengths on every project

- Manufacturing and launch expertise

- Flexible to our customers needs

- Technology & innovation specialists

- Quality & craftsmanship-focused

- Project management and execution

- We listen and always share lessons learned

Manufacturing & Engineering Services

Our services

Our manufacturing & engineering services help OEMs and Tier 1 suppliers in the automotive sector lower their costs and maximize their resources so they can focus on innovation and meeting market demand. Set the ideal conditions for your next vehicle launch (and beyond) by leveraging our expertise at every step of your project.

Manufacturing Services

Throughout your project we can provide manufacturing services that utilize our capacity and expertise so you can free up your capacity and resources and focus on tasks and projects critical to your profitability. Prototype, Pre-production, Production and Beyond.

Test, Trial, Produce

At the front-end of your project we conduct analysis to identify opportunities and blind spots to help set the ideal conditions for launch:

- Product feasibility

- Material and process trials

- Prototype part production

- Equipment and tooling selection

Trial, Optimize, Produce

The pre-production phases are critical points of learning and optimizing process prior to production. They require a tremendous amount of resources to analyze each step of the process to ensure a production capability while also providing quality parts to your customer. We can use our resources and capacity to help you develop and optimize each process, and manage and manufacture quality parts for your internal and customer needs.

- Equipment, tool, and process trials

- Complete process optimization

- Pre-production part manufacturing to support builds and testing

- Build management and coordination

- Process and quality documentation

- Lessons learned and training

Manage and Manufacture

Managing a production manufacturing facility can be very challenging. Product complexity has never been higher. Cost pressures make maintaining the proper technical staff a challenge. Volumes are inconsistent and can waste or under utilize your capacity. Utilize our team and resources help alleviate these pressures. We can manage and manufacture complex low volume projects, specialty products, and even service production

- Low volume production

- Specialty part production

- Service production

Manufacturing Capabilities

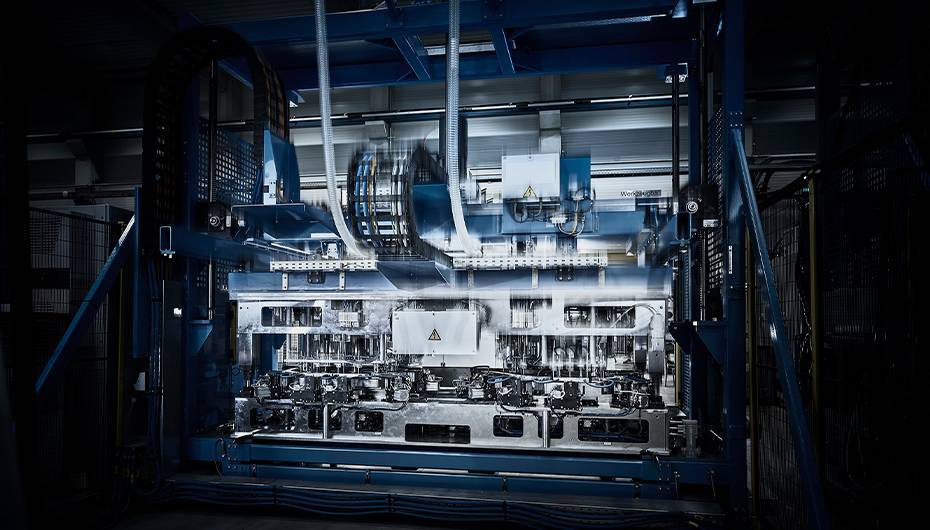

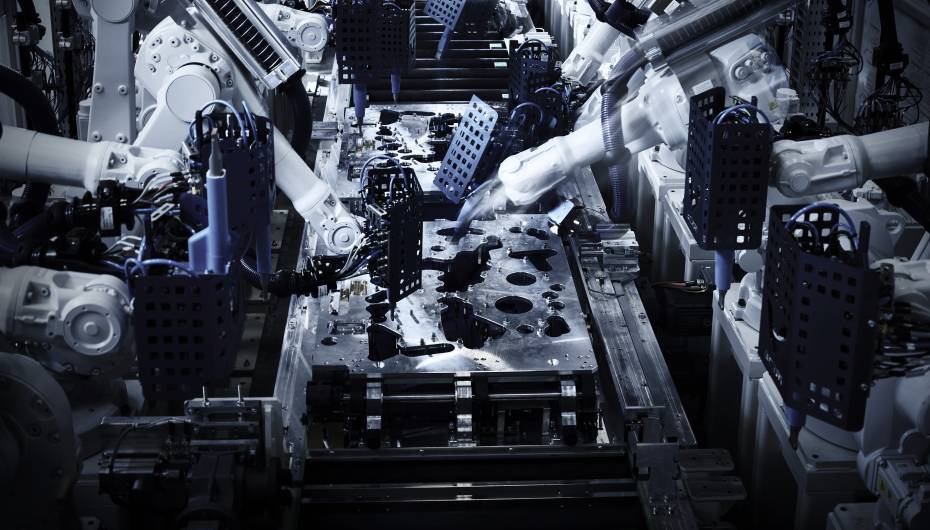

Together with our partners at 3CON, we provide world-class manufacturing solutions including the following:

Assembly

- Manual assembly experts

- Dual-position robotic assembly cell

- 3CON Robotic Flex Cell

- Assembly trunnions & fixtures

- Ultrasonic weld systems

- Electronic torque drivers

Cut & Sew

- Zünd Digital Material Cutter

- Digital pattern tracer

- Material optimization software

- Twin needle post bed sewing machines

- Single needle functional sewing machines

Presses & Lamination

- 3CON MTPS Lamination press

- 3CON IMG/IMGL Vacuum Former

- 3CON Bladder Press

Adhesive Application

- BlueMelt Roll Coater

- Spray Booths

- Flame/Plasma treat

- Dual metering spray system

- Walk in combustion oven

- Despatch forced air convection oven

Engineering Services

The challenges of maintaining technical resources and absorbing the added demands of launching a new project have never been higher. The pressures to reduce cost and optimize your performance in production are critical to your profitability. Utilize our experience and expertise to supplement and support your team.

Planning & Design Services

At the front-end of your project we conduct analysis to identify opportunities and blind spots to help set the ideal conditions for launch:

- Cost modeling & estimating

- Launch & manufacturing planning

- Technology & automation application

- Labor planning

- Work cell design

- Plant layout & material flow planning

- Project management

Analyze, plan, execute

The prototype & pre-production phases are complex and demand a lot of resources. Optimizing each process and ensuring each project can be manufactured at is targets is critical to your profitability. With our experience, we can help you ensure your launch is a success.

- Turn-key project management and integration

- Simulation modeling and analysis

- Technology identification

- Process flow evaluation and optimization

- Layout development

- Labor optimization

- Constraint analysis and through put optimization

- Launch management and execution

- Training & best practice identification

Analyze, execute

Production pressures can be relentless. Day to day challenges can make it difficult to focus and execute your improvement projects. Utilize our experience and expertise to help. We will not just give you a list. We will work shoulder to shoulder with you to identify opportunities and implement.

- Constraint analysis

- Simulation modeling

- Material and process flow analysis

- Layout optimization

- Automation and technology application

- Labor and staffing analysis

- Standard work and procedure development

Our Process

This Is How We Operate

Listen. Adjust. Learn. Succeed.

Your project will begin with our team listening and understanding your unique goals and challenges so that we can build a customized solution that fits your timeline and budget. We're happy to travel to you and will plan on viewing your operations to gauge your most pressing needs. When you work with our team you can expect prompt responses to your calls or emails and personal attention throughout your entire project. Whatever our role, in the end, we will share lessons learned with your team to ensure your long-term sustainability and success.

PROJECT

ASSESSMENT

ASSESSMENT

- Evaluate customer’s needs

- Team reviews

- Field assessments

- Develop customised proposal

ABSORPTION OF TEAM

RESPONSIBILITIES

RESPONSIBILITIES

- Feasibility and development studies

- Project planning

- Project management

- Process design

- Build supervision and coordination

- Documentation

KNOWLEDGE

TRANSFER

TRANSFER

- Inform

- Train

- Share learned lessons

- Review risks & opportunities

IDEAL LAUNCH

CONDITIONS ARE SET

CONDITIONS ARE SET

- Focused resources

- On time execution

- Process optimized

- Equipment and tools validated

- Team trained

- Below budget

FREQUENTLY-ASKED QUESTIONS

ABOUT WORKING WITH AUTOBRIDGE

No, but we can guarantee your launch will be better with us, than without.

Our engagement is dependent on the project, but always starts with us understanding your project scope and determining where we can help bridge your gaps. We are always open to you reaching out to us directly and discussing how to help with your project.

We have years of extensive launch experience and have lived the pain of launches and day-to-day production so we know how to set the stage for a successful launch --and beyond. Our manufacturing expertise can help us determine the best path forward so we can save you time and money. You can learn more about us on our team page.

By flexing to your needs, we can help you maintain a steady-state workforce. We can absorb the extra demands of a launch and allow your team to focus on their core responsibilities. We can reduce your non-value added costs such as excessive travel, premium freight, and containment & compression costs. Additionally, we can provide flexible space and equipment capacity that will allow you to keep your core assets prioritized on optimizing the profitability of your current production. We will work with you to focus on getting things done right the first time. Our early focus on waste elimination and commissioning will pave the path to lower cost to the plant.

Yes, we can adjust to your needs and help you meet your production goals, regardless of quantity.

We are available to help with all life cycles of vehicle launch from planning to prototype to production.

We're located in the same building, and have common global leadership, making it easy to collaborate with 3CON to fulfill your needs. Their experience in tooling and equipment helps us set you up for a successful launch – from prototype to production.

Get in touch with us

Autobridge Inc.

47295 Cartier Dr.

Wixom/Michigan 48939, USA

T: 947 214 9065

E:

Hours of operation

Monday-Friday

7:00 am to 5:00 pm (EST)